Inverted high speed wire drawing machine is an industrial machine used to draw metal wire at high speeds while reducing the diameter of the wire through a series of drawing dies. The term "inverted" r...

See Details

The production of high-quality metal hardware products relies on state-of-the-art machinery and innovative processing technologies. Wire drawing machines, for instance, play a pivotal role in shaping metal wires, rods, and tubes into precise diameters and smooth surfaces, ensuring uniformity and durability for applications such as fasteners, springs, and decorative components. Equipped with automated controls and adjustable tension systems, modern wire drawing machines enhance efficiency while minimizing material waste.

Products: Steel wire, copper wire, aluminum wire, alloy wire, etc. Application: Used as basic metal materials for further processing into industrial components or semi-finished products.

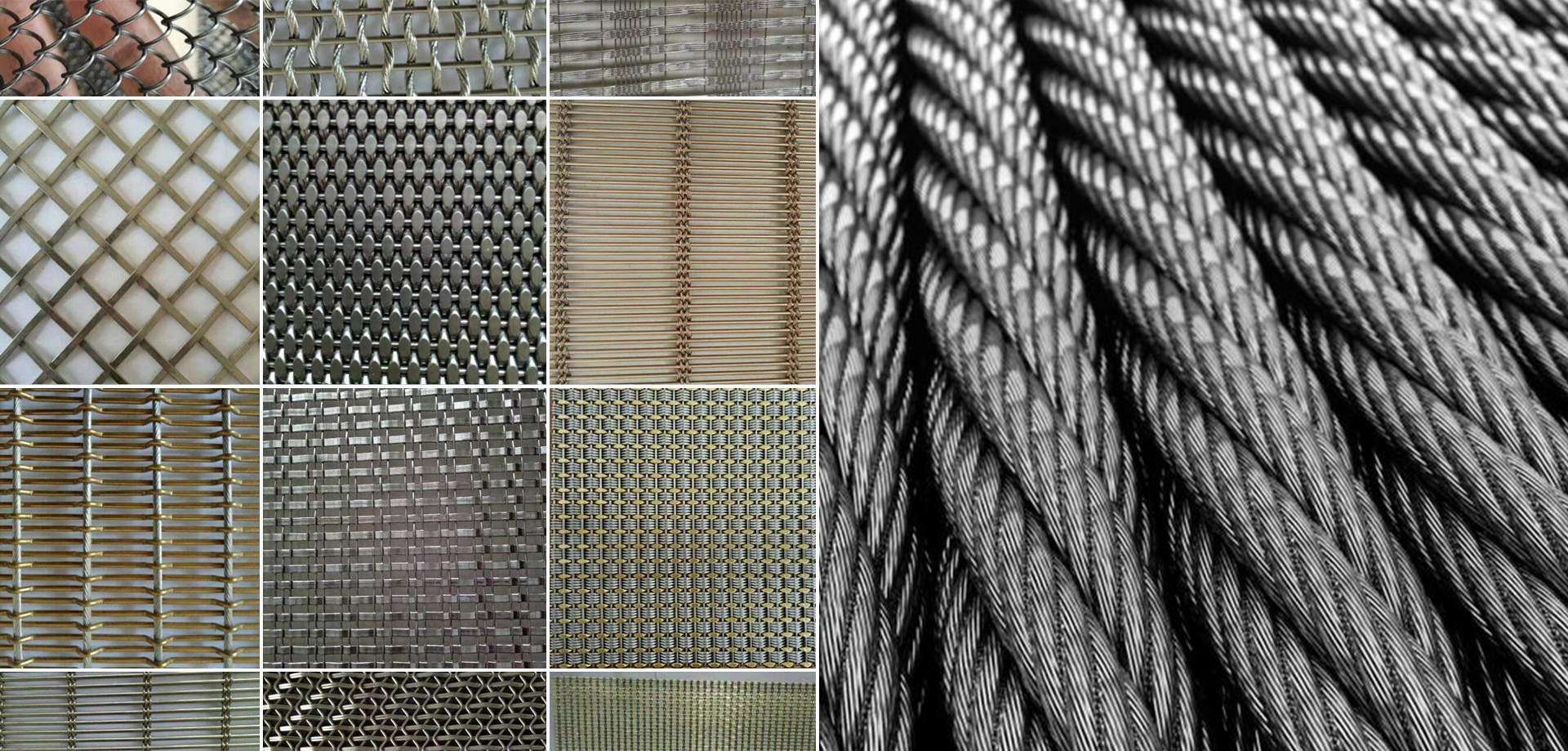

Products: Prestressed steel wire, cold-drawn steel bar, steel strand, metal mesh, etc. Application: Used for concrete reinforcement (such as bridges and building structures), fencing, protective meshes, and other building materials.

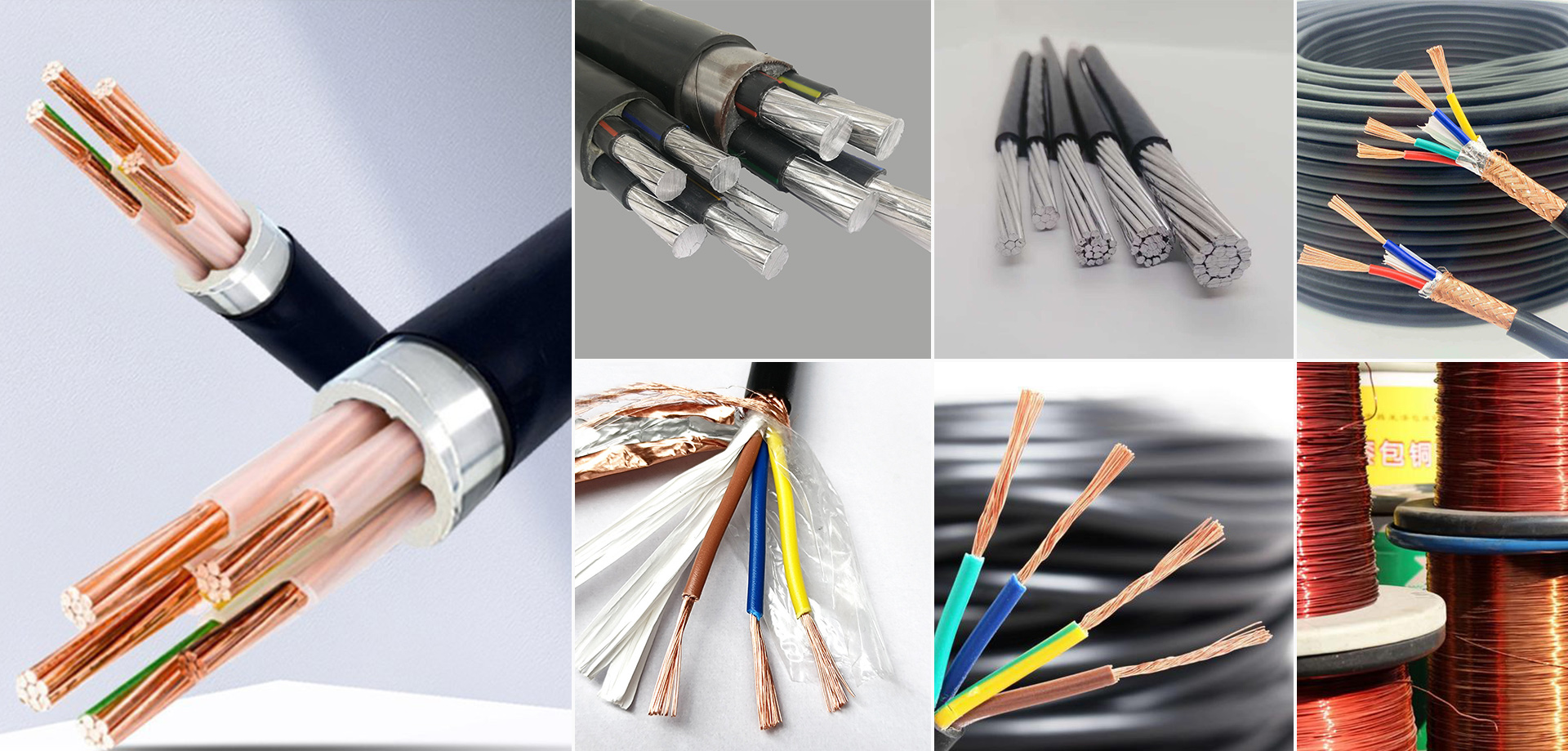

Products: Conductor cores (copper wires, aluminum wires), enameled wires, shielded wires, etc. Application: Serving as the conductive core materials for wires and cables, used in power transmission, electronic devices, and other fields.

Products: Brake cables, suspension springs, drive shaft components, precision metal wires, etc. Application: Automotive components require high strength and precision, and the wire drawing process can enhance the material performance.