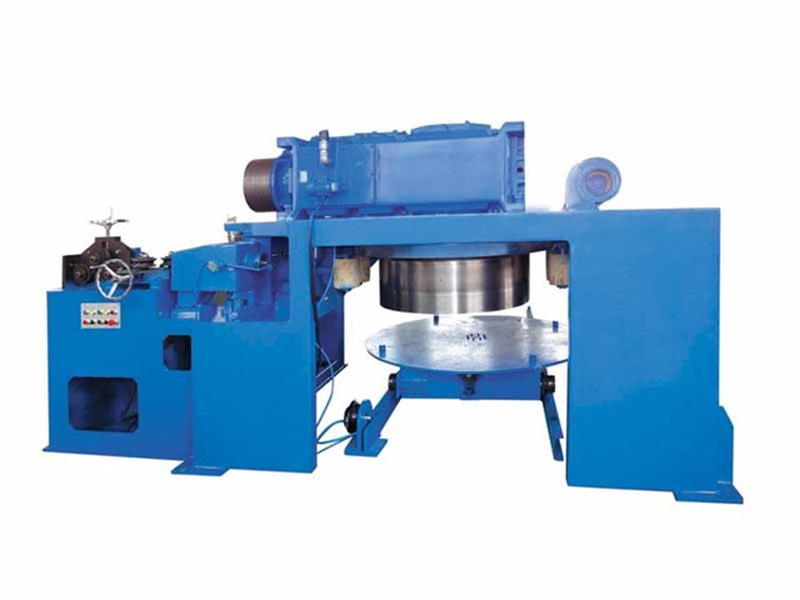

The single channel inverted wire drawing machine is a wire drawing equipment designed to reduce the wire diameter in a controlled and precise manner. Unlike the traditional upright wire drawing machine, the inverted wire drawing machine is characterized by its unique design, in which the wire drawing unit is inverted, an orientation that offers several advantages in terms of space efficiency, ease of maintenance, and improved control over the wire drawing process. The motor is the core of the wire drawing machine, providing the power required to pull the wire through the wire drawing die. The drive system is connected to the motor and is responsible for transmitting the rotational motion to the wire drawing device. The speed and torque of the motor can be adjusted to suit different wires and the required Brushed specifications. The notable feature of the inverted wire drawing machine is the drawing frame, which holds the drawing dies and is placed upside down to facilitate gravity-assisted drawing. The wire enters the machine from the top and is drawn downwards, passing through a series of progressively smaller dies, gradually reducing in diameter. Inverted racks offer several benefits such as reduced wire loading, longer die life and enhanced wire tension control. High-speed wire drawing creates a lot of friction, which can cause overheating and wear of the die and the wire itself. To alleviate this, the single-frame inverted wire drawing machine is equipped with a lubrication system that applies a lubricant to the wire as it passes through the die. A layer of lubricant, lubrication reduces friction, prevents overheating and improves the surface finish of the wire.

English

English русский

русский عربى

عربى