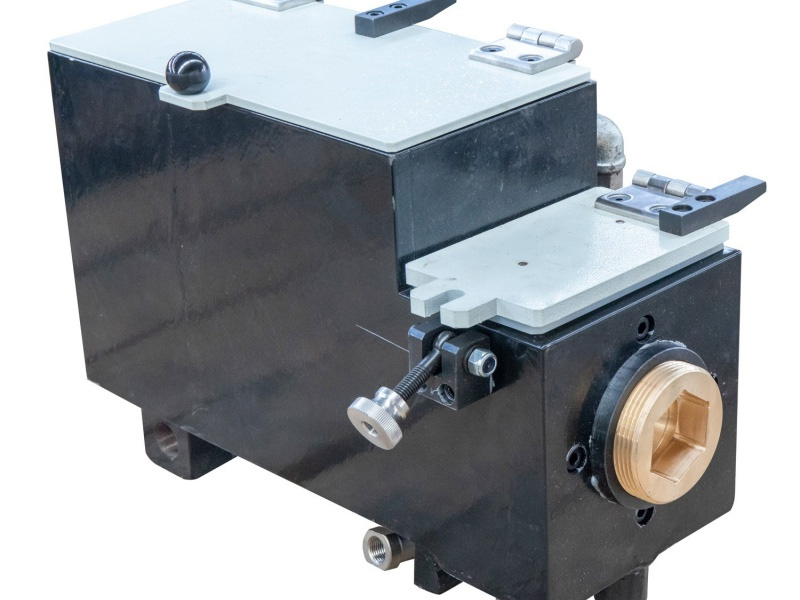

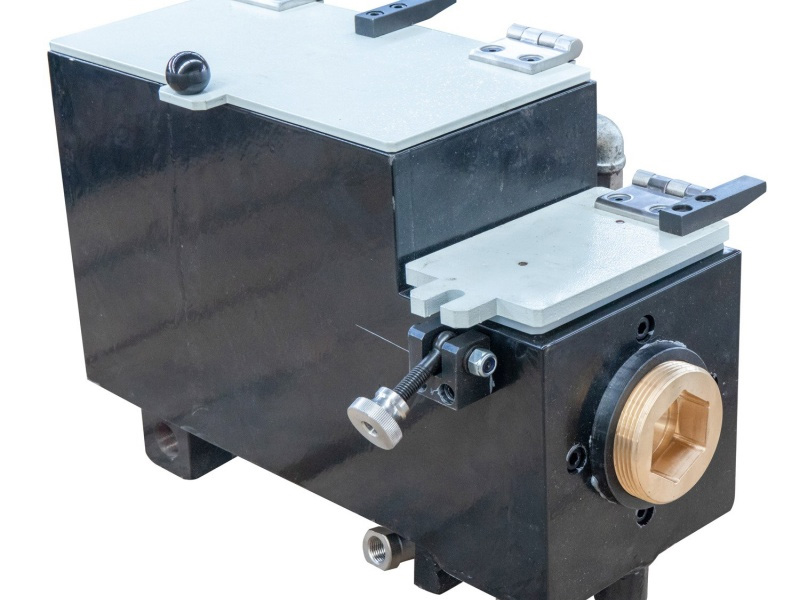

The water-cooled mold box is a device that uses water as a coolant to regulate the temperature of the mold during the casting, molding, or forming process. These boxes are made of materials with high thermal conductivity and contain water channels through which water circulates. The cooling process helps dissipate the heat generated by the molten material in the mold, allowing the material to solidify faster and more evenly. Water-cooled mold boxes are primarily used in metalworking, casting, and injection molding operations, where temperature control plays a key role in determining the outcome of the product. The cooling process helps to quickly solidify the material, prevent overheating, and reduce the possibility of defects such as warping, cracking, or surface unevenness. By effectively managing the cooling rate, these mold boxes help improve productivity, cost-effectiveness, and product quality. Water-cooled mold boxes are used in industries involving high-temperature processes, such as metal casting, plastic injection molding, and rubber processing. They are designed to work with molding machines and are available in a variety of sizes, configurations, and designs, depending on the specific needs of the application.

English

English русский

русский عربى

عربى