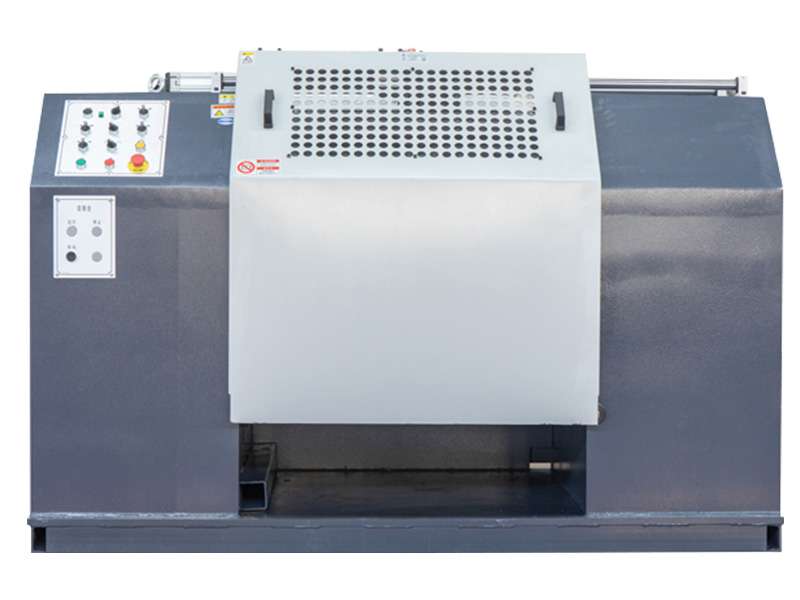

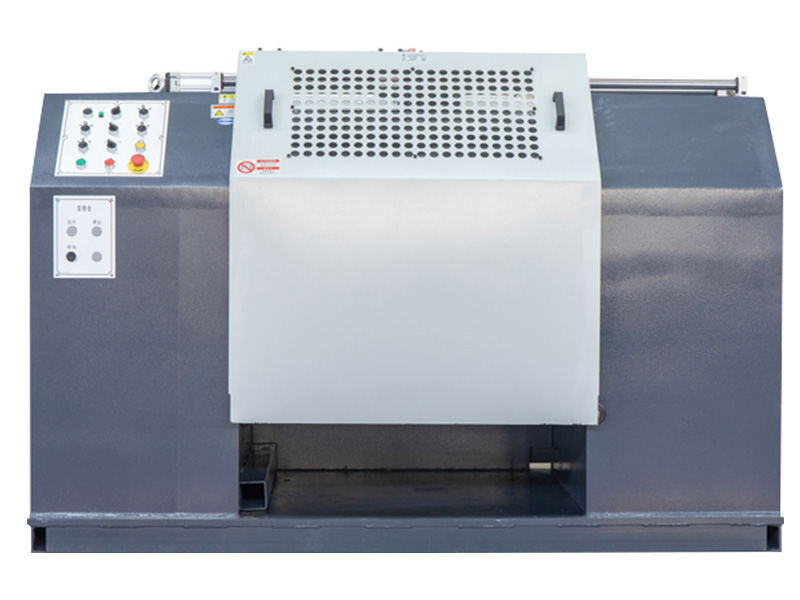

The design of the Spool take-up machine for wire drawing machine for Wire Drawing Machine emphasizes precision and efficiency. The combination of mechanical design principles, automation and modern technology enables this machine to handle a wide range of wire materials, including copper, aluminum, steel and other alloys. Its main function is to collect the drawn wire and ensure that it is wound onto the spool in an organized and compact manner to maintain the integrity of the wire shape. The winding speed and tension can be adjusted according to the type and thickness of the wire being processed to ensure that the wire is not deformed or at risk of damage when stored. The major feature of the Spool take-up machine for wire drawing machine for Wire Drawing Machine is its advanced automation system, which simplifies the winding process. The machine's control system includes a PLC (Programmable Logic Controller) to manage various aspects of winding, such as speed control, tension adjustment and spool rotation. This automation ensures consistent, high-quality output with minimal human intervention. The machine is versatile and can handle wires of different diameters, materials and coil sizes. Whether winding small diameter wires for delicate electrical applications or large diameter wires for industrial use, the winding machine can meet various requirements. The adjustable spindle design allows the use of a variety of spool sizes, providing production flexibility.

English

English русский

русский عربى

عربى